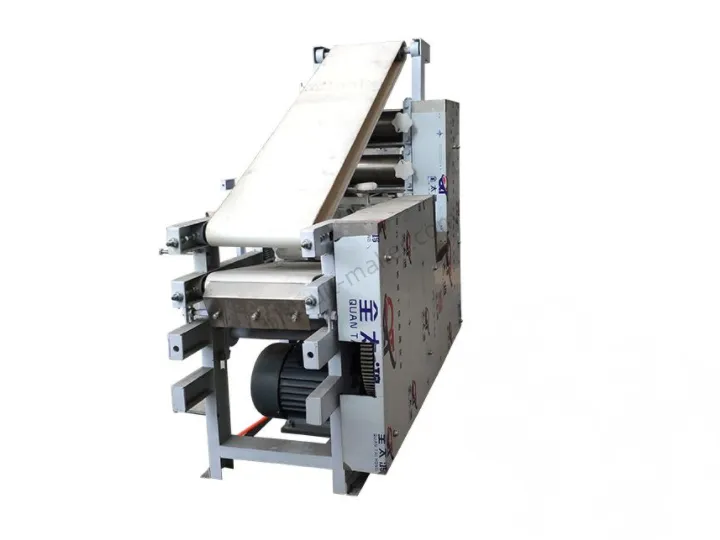

Automate your flatbread production with our commercial Pita Bread Making Machine. This machine is a high-efficiency dough former, engineered to press and cut perfect, uniform dough skins every time. It is the core component for businesses wanting consistency and speed in their flatbread production.

What Is the Pita Bread Making Machine?

This is an automatic dough forming machine. It is a specialized flatbread press that integrates two stages into one seamless process: it first sheets the dough to a perfect thickness, then immediately cuts it to your desired shape.

- Input: You feed it prepared dough balls or dough sheets.

- Output: It produces perfectly shaped, unbaked flatbread skins (like raw pita or tortilla).

It can be used as a standalone unit for manual baking or integrated into a full production line with a tunnel oven.

Key Features of the Arabic Bread Making Machine

- Incredible Versatility: This is not just a pita bread making machine. By simply changing the mold, it becomes an Arabic bread making machine, a tortilla press machine, a roti maker, or a chapati forming machine. Produce a wide variety of flatbreads using a single piece of equipment.

- Total Product Customization:

- Adjustable Thickness: Precisely control the thickness from 1mm to 6mm.

- Custom Molds: We create molds for any size and shape you need—round, oval, square, and more.

- High Efficiency: Achieve consistent, high-speed output that manual labor cannot match. Boost your production capacity instantly.

- Perfect Consistency: Every flatbread skin is identical in size, shape, and thickness. This guarantees a uniform final product for your customers.

- Durable & Hygienic: Built with a stainless steel body and a food-grade PVC conveyor belt for long service life and easy cleaning.

How does the Lebanese Bread Maker Work?

The working principle of the pita bread making machine is simple and effective:

- Dough Input: An operator places prepared dough onto the machine’s inlet.

- Pressing & Sheeting: The machine’s rollers press the dough into a continuous sheet of your desired thickness.

- Cutting & Forming: A custom-shaped mold descends and cuts the dough sheet into perfect individual skins.

- Waste Separation: The excess dough lattice is automatically separated for reuse.

- Output: The finished dough skins are neatly placed on the output conveyor, ready for the next step.

How to Apply this Machine?

This flatbread dough former is flexible for any production scale.

- In an Automatic Production Line: Connect the machine’s output conveyor directly to a tunnel oven. This creates a fully automated line for continuous baking. This setup is ideal for large-scale producers.

- As a Standalone Machine: Use the machine to rapidly produce dough skins. Operators can then manually collect the skins to bake on a griddle, in a tandoor oven, or using other traditional methods. This is perfect for restaurants, bakeries, and startups.

Various Models for Your Business

Learn some main data of our hot-selling pita bread making machines. We also provide customized machines for your needs.

| Model | TZ-300/350/400/450/500/550/600 |

| Power | 2.2 kW |

| Bread Thickness Range | 1-6 mm(Adjustable) |

| Max Round Diameter | 25/30/35/40/45/50/55 cm |

| Machine Materials | Stainless steel body, food-grade PVC conveyor belt |

| Voltage | 220V or 380V options available. |

| Warranty | One year free |

Get a Quote for Your Pita Bread Making Machine

Let us help you find the perfect machine. For a fast and accurate quote, please tell us:

- The shape and diameter of your flatbread?

- Your desired thickness?

- Your local voltage requirements?

Contact us today to improve your production efficiency!