Meet global demand with a single, powerful solution. Our fully automatic Arabic Bread Production Line is a turnkey system engineered for the high-volume manufacturing of world-famous breads. Engineered specifically for creating the perfect Pita Bread with a consistent pocket, this modular solution is the definitive choice for producers worldwide. While specializing in Khubz and Lebanese Bread, this versatile system is a complete Flatbread Solution, also capable of producing Roti, Lavash, and a wide range of other baked goods. Partner with us to capture the lucrative Arabic bread market.

Customized Equipment in Arabic Bread Production Line

Our integrated line is built from world-class components that you can choose and configure. This is more than just pita bread making machines; it’s your personalized factory.

Dough Mixing: Choose Your Technology

- Option A: Vacuum Dough Mixer (For Premium Quality): Our top-tier option. It operates under a vacuum, producing a harder, denser, square-shaped dough with superior gluten development. With variable speed control, it’s the ideal choice for high-end products like premium noodles and dumpling wrappers where texture is paramount.

- Option B: Planetary / Spiral Mixer (For Versatility): This constant-speed workhorse is a multi-functional marvel. By simply changing the mixing head, you can switch from a dough hook for bread to a whisk for whipping cream or a beater for mixing fillings. It’s the perfect, cost-effective choice for bakeries with diverse product lines.

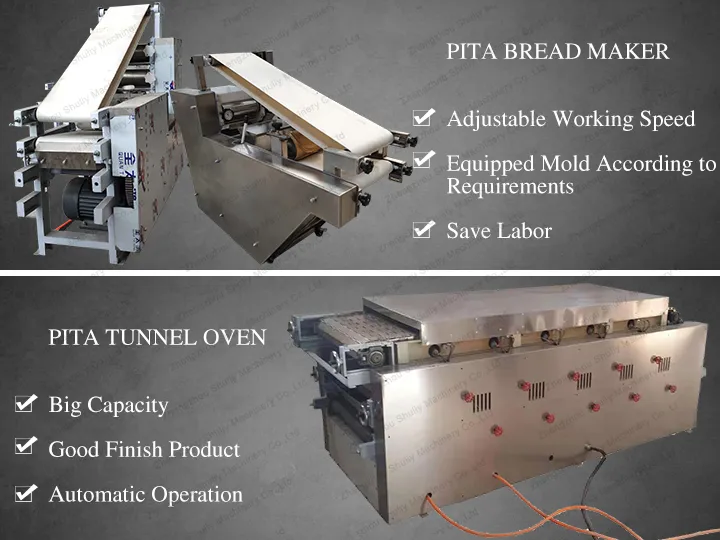

Sheeting & Forming: Precision and Customization

The dough proceeds to our industrial dough sheeter for perfect thickness, then to the forming machine. The forming molds are fully customizable to any shape or size you require, from a classic round Pita to a unique brand shape.

Baking or Freezing: Select Your Path to Market

- Option A: Chain Mesh Belt Tunnel Oven (Recommended): This continuous oven ensures perfect, even baking and is essential for achieving the high-temperature “flash bake” needed for the Pita pocket effect. It integrates seamlessly with our cooling conveyor for a fully automated line. While it represents a higher initial investment, it delivers the highest quality and efficiency.

- Option B: Single-Layer Baking Oven (Economical Choice): A more budget-friendly option suitable for various flatbreads, perfect for businesses starting out or with specific product needs.

Beyond Flatbread: Unlock New Products with Modular Upgrades

Our arabic bread production line’s greatest strength is its incredible flexibility. Here’s how you can easily adapt it to produce other popular foods:

Create a Flaky Pastry & Stuffed Pie Line

By integrating a filling and encrusting machine before the oven, your flatbread line instantly transforms. You can produce delicious stuffed pastries, flaky pies, and products like Asian Su Bing with savory or sweet fillings.

Produce Lotus Leaf Buns

It’s simple. We provide a custom lotus leaf bun mold for the forming machine and add our specialized automatic folding unit after the cutter. The machine will cut, fold, and create the classic bun shape, ready for steaming.

Enter the Frozen Dough Market

What about products that require special baking methods, like Tandoor-baked Naan? We offer a highly profitable alternative. Instead of an oven, we can configure the line with a high-efficiency IQF quick freezer and a packaging machine. You can produce and sell high-quality frozen, unbaked dough products directly to restaurants, hotels, and supermarkets, letting them do the final bake.

Your Custom Production Solution Awaits

We don’t believe in one-size-fits-all. We believe in building the perfect solution for you. Whether you need a high-end vacuum mixer with a tunnel oven for premium Pita, or a versatile planetary mixer that feeds into a freezer for a frozen dough business, our engineers will design the system that meets your products, your space, and your budget.

Stop searching for a standard machine. Let’s build your unique production line together. Contact our engineering team today for a personalized consultation and a detailed proposal for your custom-built Arabic Bread Production Line.

Main Parameters of Our Pita Bread Production Line

| Parameter | Details / Configuration |

|---|---|

| Product Name | Automatic Pita & Arabic Bread Production Line |

| Model | ABP-Series |

| Production Capacity | Customized by your needs |

| Key Applications | Pita Bread, Arabic Bread (Khubz), Lebanese Bread |

| Extended Applications | Roti, Chapati, Flour Tortillas, Lavash, Naan (frozen dough), Flaky Pastry, Stuffed Paratha, Lotus Leaf Buns, etc. |

| Finished Product Size | Diameter: 5 cm – 45 cm (Adjustable by changing forming molds) |

| Key Machine Configuration | Dough Mixer: Optional Vacuum Dough Mixer or Planetary/Spiral Mixer Dough Sheeter: Continuous Multi-Roller System Forming Machine: Fully Customizable Molds Cooking Unit: Optional Chain Mesh Belt Tunnel Oven or IQF Spiral Freezer |

| Construction Material | All food-contact parts are made of Food-Grade SUS304 Stainless Steel |

| Heating & Power | Heating Source: Electric Power Supply: Customized to the client’s factory standard (e.g., 380V/50Hz/3P) |

| Line Dimensions | Customized according to the final equipment configuration. We provide a complimentary factory layout design service. |

| Optional Upgrades | Filling Machine, Automatic Folding Unit, Dough Laminator |

| After-Services | One year free warranty, on-site installation, technical guidance, etc. |