آلة قطع كرات العجين أداة أساسية للمخابز والمطاعم والمصانع الغذائية التي تحتاج إلى تقسيم قطع العجين الكبيرة بسرعة ونظافة. سواء لإنتاج الخبز، الشباتي، البيتزا، أو الكوكيز، تضمن هذه الآلة حجم وشكل عجين متسق، وتقليل العمل اليدوي وتحسين كفاءة الإنتاج.

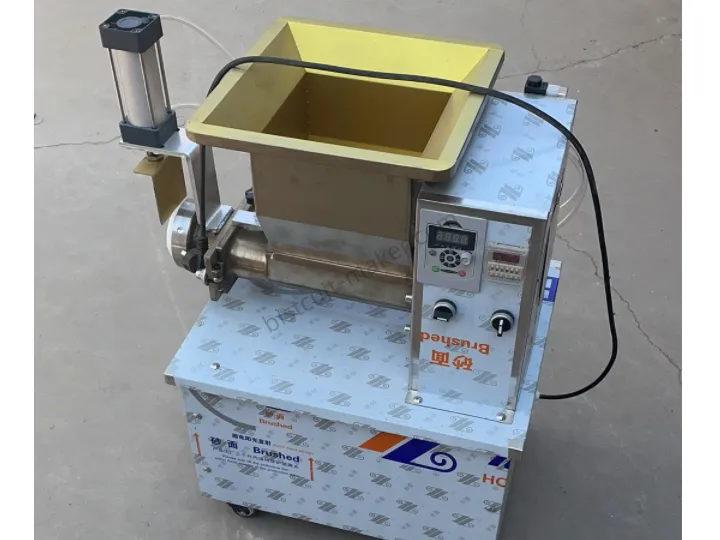

صنعت بواسطة معدات الطعام Taizy، مصنوعة من الفولاذ المقاوم للصدأ من الدرجة الغذائية، مزودة بشفرات متينة ونظام قطع مستقر، مما يجعلها مثالية للاستخدام التجاري المستمر.

الميزات الرئيسية ومزايا آلة قطع عجين الكوكيز

- القطع الموحد: كل كرة عجين لها نفس الوزن والحجم.

- الفولاذ المقاوم للصدأ الغذائي: مقاوم للتآكل وسهل التنظيف.

- حجم الكرة قابل للتخصيص: من كرات عجين الكوكي الصغيرة إلى أجزاء العجين الكبيرة للخبز أو البيتزا.

- توافق واسع مع الجهد الكهربائي: يعمل مع مصدر طاقة 220 فولت أو 380 فولت.

- تصميم مدمج: موفر للمساحة وسهل الدمج في الخطوط الحالية.

- تكلفة عمل منخفضة: القطع التلقائي الكامل يقلل من التعامل اليدوي.

نوعان من قواطع كرات العجين

آلة قطع كرات العجين الكهربائية

يستخدم هذا النموذج محركًا كهربائيًا كمصدر طاقة رئيسي. مناسب للإنتاج الصغير إلى المتوسط في المخابز ومحلات الحلويات والمطاعم.

- الجهد القياسي: 220 فولت/380 فولت (قابل للتخصيص)

- تتميز بتشغيل مستقر وضوضاء منخفضة

- حجم مدمج، سهل النقل والصيانة

آلة قطع كرات العجين الهوائية

مدفوعة بالهواء المضغوط، توفر هذه النسخة قوة قطع أعلى وتشغيل أكثر سلاسة، مثالية لمعالجة العجين الصناعية.

- ضغط هوائي قابل للتعديل لمتانة العجين المختلفة

- تقطيع موحد وتقليل تشوه العجين

- مثالية للإنتاج المستمر على نطاق واسع

كيف تعمل آلة قطع كرات العجين؟

مبدأ عمل آلة قطع كرات العجين من Taizy بسيط وفعال. بعد وضع العجين المُعد في الخزان، تقوم الآلة تلقائيًا بتغذية العجين نحو الشفرات الدوارة أو الرأس القطع الهوائي.

- في النوع الكهربائي، يدير محرك القطع للدوران بسرعة ثابتة. يتم فرد العجين وتقطيعه إلى كرات أو قطع متساوية.

- في النوع الهوائي، يوفر أسطوانة هوائية ضغطًا أقوى للأسفل، مثالي للعجين السميك أو الكثيف مثل خبز، شباتي، أو عجين البيتزا. يضمن النظام الهوائي أن يكون كل قطع دقيقًا ومتسقًا.

يمكن تخصيص كلا النوعين لأحجام كرات مختلفة، وأشكال الشفرة، وسعات الإنتاج، وفقًا لمتطلبات الإنتاج الخاصة بك.

تطبيقات آلة قطع عجين الخبز

يُستخدم على نطاق واسع آلة قطع كرات العجين في:

- مخابز ومصانع المعجنات: لتقسيم كرات العجين بشكل متساوٍ قبل التخمير.

- خطوط إنتاج البيتزا والمعجنات: لضمان حصة عجين متسقة لكل قشرة.

- معالجة عجين الكوكيز: تعمل كآلة قطع عجين الكوكيز أو مقسم للعجين.

- إنتاج الشباتي، الروتي، والخبز المسطح: مثالية كآلة قطع كرات الشباتي.

يمكن دمجه أيضًا مع عجائن الخلاطات ، آلات فرد العجين ، أو آلات التشكيل لخط إنتاج خبز عربي آلي بالكامل أو خط إنتاج البسكويت .

المعلمات الفنية لآلة قطع عجين البيتزا الخاصة بنا

| عنصر | الوصف |

|---|---|

| نموذج | كهربائي أو هوائي |

| الجهد االكهربى | 220 فولت / 380 فولت (قابل للتخصيص) |

| حجم القطع | قابل للتعديل (عن طريق القالب أو الشفرة) |

| سعة | 30–80 كجم/ساعة (حسب نوع العجين) |

| المادة | الفولاذ المقاوم للصدأ من الدرجة الغذائية |

| التطبيق | كرات العجين للخبز، البيتزا، الكوكيز، الشباتي، وغيرها. |

لماذا تختار آلة قطع العجين Taizy؟

تخصص Taizy في تصنيع آلات معالجة الطعام عالية الدقة وموثوقة. تُصدر آلات قطع كرات العجين الخاصة بنا إلى العديد من البلدان، وتستخدم على نطاق واسع في المخابز والمطاعم والمصانع الغذائية. نقدم خدمة تخصيص كاملة—سواء كنت بحاجة إلى آلة قطع عجين الكوكيز، أو قاطع عجين الخبز، أو مقسم كرات عجين البيتزا، يمكن لـ Taizy توفير الحل المناسب لعملك.

يتم اختبار كل وحدة بعناية قبل التسليم، لضمان أداء مستقر وسهولة في التشغيل وطول عمر الخدمة.

الختام

آلة قطع كرات العجين من Taizy هي خيار مثالي لأي شخص يبحث عن تحسين كفاءة معالجة العجين وتحقيق جودة متسقة. مع خيارات لكل من الأنظمة الكهربائية والهوائية، فهي تتكيف مع مجموعة واسعة من بيئات المخابز وإنتاج الأغذية.